使用焊接機(jī)器人保證其質(zhì)量要做到什么

來(lái)源:http://www.camtask.com/ 發(fā)布時(shí)間:2022-12-29 瀏覽次數(shù):0

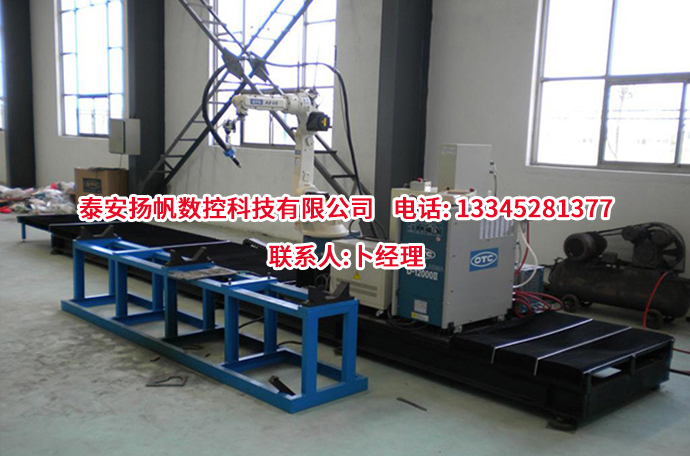

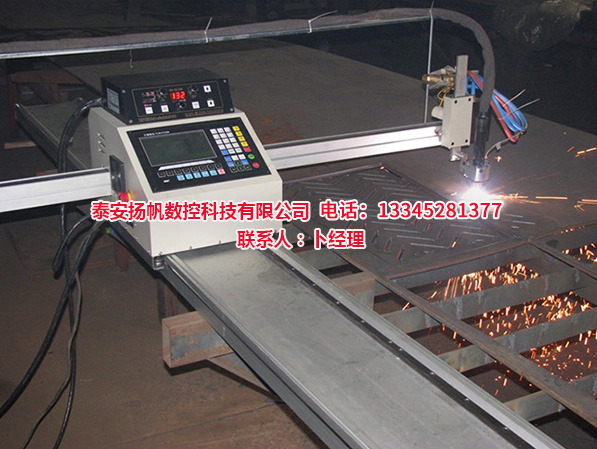

想要保證焊接機(jī)器人的工作質(zhì)量,離不開(kāi)技術(shù)人員對(duì)設(shè)備的應(yīng)用方法以及對(duì)設(shè)備的保養(yǎng),畢竟一個(gè)劣質(zhì)的設(shè)備,生產(chǎn)出的產(chǎn)品質(zhì)量也是無(wú)法保證的。那么使用焊接機(jī)器人保證其質(zhì)量要做到什么?山東焊接專(zhuān)機(jī)廠家為您講解。

To ensure the working quality of the welding robot, it is necessary for technicians to apply the equipment and maintain the equipment. After all, a low-quality equipment can not guarantee the quality of the products produced. What should be done to ensure the quality of welding robots? Shandong welding machine manufacturer will explain to you.

一、焊接機(jī)器人檢查和維護(hù)

1、 Inspection and maintenance of welding robot

1、送絲機(jī)構(gòu)。包括送絲力是否正常,送絲管是否受損,是否有異常報(bào)警。

1. Wire feed mechanism. Including whether the wire feeding force is normal, whether the wire feeding tube is damaged, and whether there is abnormal alarm.

2、檢查氣流是否正常。

2. Check whether the air flow is normal.

3、割炬保護(hù)系統(tǒng)是否正常。等等。

3. Whether the cutting torch protection system is normal. wait.

二、周檢查和維護(hù)

2、 Weekly inspection and maintenance

1、擦洗焊接機(jī)器人的軸。

1. Scrub the shaft of the welding robot.

2、檢查T(mén)CP的準(zhǔn)確性。

2. Check the accuracy of TCP.

3、檢查殘留物的油位。

3. Check the oil level of the residue.

4、檢查機(jī)器人各軸的零位是否準(zhǔn)確。等等。

4. Check whether the zero position of each axis of the robot is accurate. wait.

三、焊接機(jī)器人每月檢查和維護(hù)

3、 Monthly inspection and maintenance of welding robot

1、潤(rùn)滑機(jī)器人的軸。其中,16軸為白色,帶潤(rùn)滑油。

1. Lubricate the axis of the robot. Among them, shafts 1 to 6 are white with lubricating oil.

2、帶黃油的RTS導(dǎo)軌的RP定位器和紅色噴嘴。

2. RP positioner and red nozzle for RTS rail with grease.

3、RP定位器上的藍(lán)色潤(rùn)滑脂和灰色導(dǎo)電油脂。等等。

3. Blue grease and grey conductive grease on the RP positioner. wait.

8.除1-8的工作外,完成每周檢查的所有項(xiàng)目。

8. In addition to the work in 1-8, complete all items checked every week.

9、設(shè)備故障時(shí),應(yīng)立即維修,報(bào)告維修情況,詳細(xì)說(shuō)明故障前設(shè)備的狀況和運(yùn)行情況,并協(xié)助維修人員進(jìn)行檢查,順利恢復(fù)生產(chǎn)。主管將對(duì)設(shè)備保養(yǎng)情況進(jìn)行不定期抽查。操作者在每班交接時(shí)仔細(xì)檢查設(shè)備狀況是否完好,記錄好各班設(shè)備運(yùn)行情況。

9. In case of equipment failure, it is required to repair immediately, report the repair situation, specify the condition and operation of the equipment before the failure, and assist the maintenance personnel in inspection to successfully resume production. The supervisor will conduct random inspection on equipment maintenance. The operator shall carefully check whether the equipment is in good condition during each shift handover, and record the equipment operation of each shift.

設(shè)備故障時(shí),維修部門(mén)應(yīng)當(dāng)及時(shí)反映設(shè)備狀況,包括故障時(shí)間、故障現(xiàn)象和故障前后情況,經(jīng)營(yíng)者應(yīng)當(dāng)向維修人員詳細(xì)說(shuō)明,以糾正和快速排除故障。更多有關(guān)設(shè)備的事項(xiàng),就來(lái)關(guān)注我們網(wǎng)站http://www.camtask.com!

In case of equipment failure, the maintenance department shall timely reflect the condition of the equipment, including the failure time, failure phenomenon and the situation before and after the failure. The operator shall explain in detail to the maintenance personnel to correct and quickly eliminate the failure. For more information about equipment, please follow our website http://www.camtask.com !

上一篇:自動(dòng)焊接設(shè)備焊接鋼件抗壓強(qiáng)度不足的解決

下一篇:焊接專(zhuān)機(jī)中的操作軟件及弧焊軟件包如何?